In recent years, there has been a growing interest in the use of Wood-Plastic Composite (WPC) materials in construction, including the application of WPC wall panels.

WPC wall panels are known for their durability, low maintenance, and aesthetic appeal.

However, concerns regarding their fire resistance have arisen, especially in light of building safety regulations and the need for fire-resistant materials.

This essay aims to explore the fire-resistant properties of WPC wall panels and discuss their suitability in fire-prone environments.

I. Understanding WPC Wall Panels:

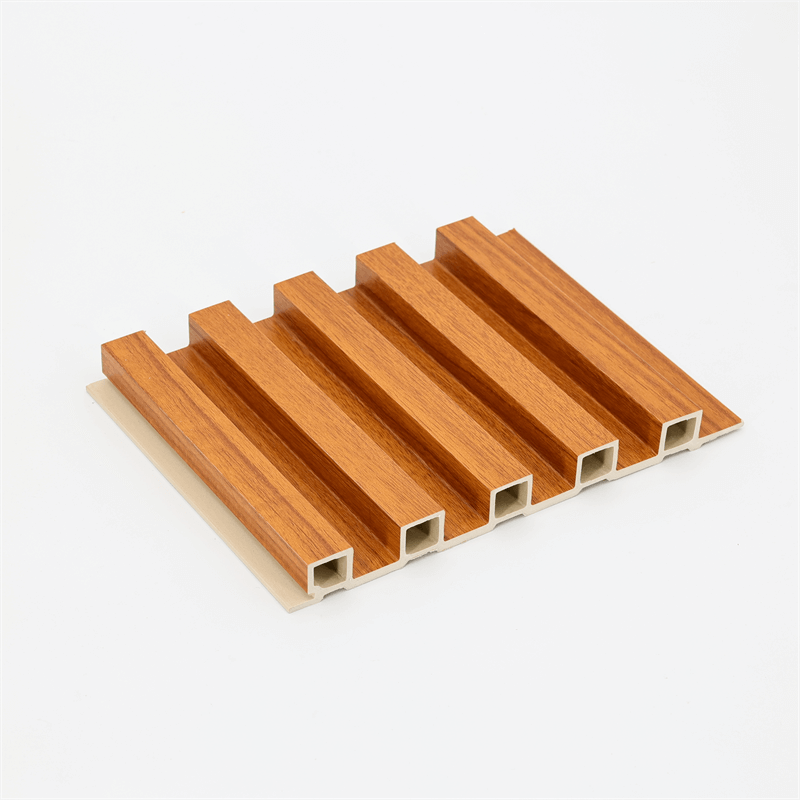

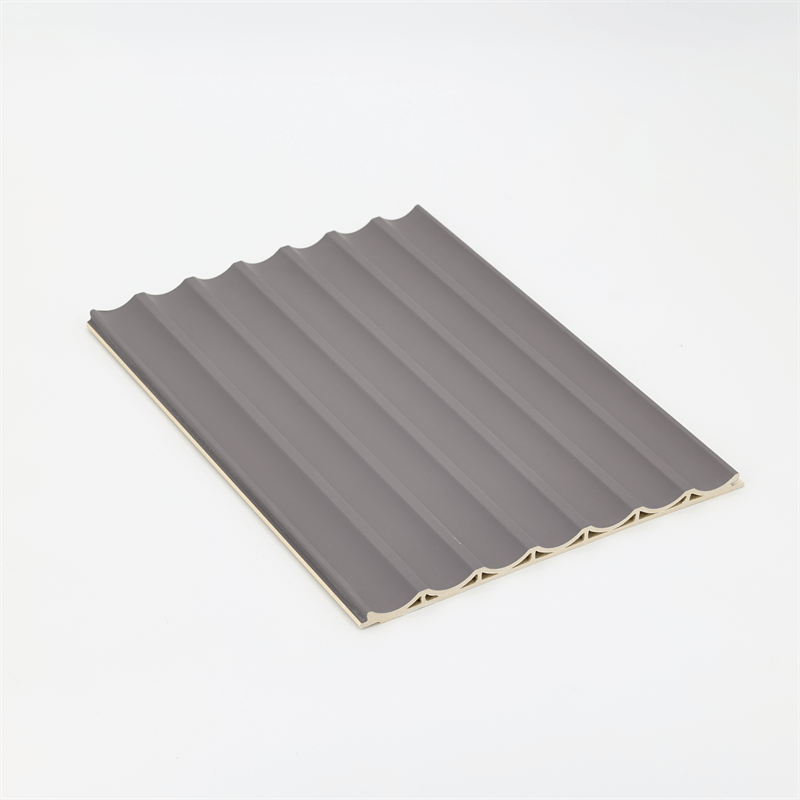

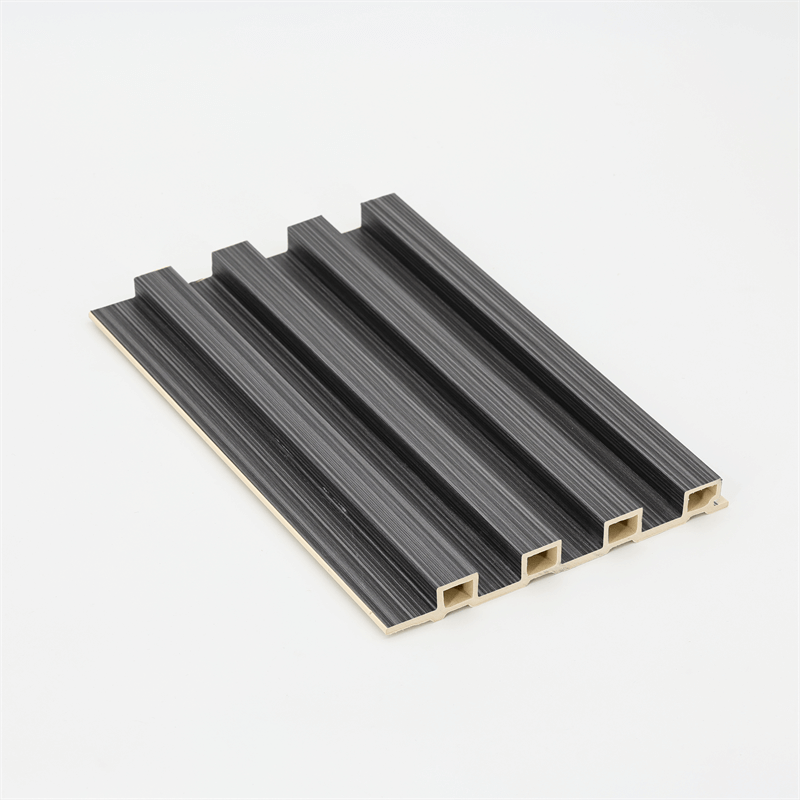

To comprehend the fire-resistant properties of WPC wall panels, it is essential to first understand the composition of these materials.

WPC wall panels are typically made by combining wood fibers or flour with thermoplastic polymers, such as polyethylene or polypropylene.

The combination of these components results in a material that exhibits the visual appeal of wood while possessing the durability and moisture resistance of plastic.

However, the combustibility of wood poses a potential risk, warranting a thorough examination of the fire-resistant properties of WPC wall panels.

II. Fire Performance Testing:

Various fire performance tests are conducted to evaluate the behavior of WPC wall panels under fire conditions.

These tests typically assess critical factors such as ignition resistance, flame spread, smoke development, and heat release rate.

Standards like ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials) and ASTM E119 (Standard Test Methods for Fire Tests of Building Construction and Materials) provide guidelines for evaluating the fire resistance of materials.

By subjecting WPC wall panels to such tests, researchers and manufacturers can determine their fire performance and compliance with safety regulations.

III. Enhancing Fire Resistance through Additives and Treatment:

To improve the fire-resistant properties of WPC wall panels, additives and treatments are often employed.

Flame retardant additives can be incorporated during the manufacturing process to reduce the combustibility of the material.

These additives work by hindering the ignition and spread of flames, thus enhancing the fire resistance of the WPC panels.

Additionally, surface treatments and coatings can be applied to create a protective barrier that retards the progress of fire and minimizes smoke emission.

IV. Considerations for Fire-Prone Environments:

When considering the use of WPC wall panels in fire-prone environments, several factors must be taken into account.

First and foremost, compliance with local building codes and regulations is crucial to ensure the safety and legality of construction projects.

Additionally, the specific fire performance requirements of the intended application should be considered.

For instance, WPC wall panels used in commercial buildings may be subject to more stringent fire safety regulations compared to residential applications.

Proper installation and maintenance of the WPC panels are also essential to maintain their fire-resistant properties over time.

In conclusion, the fire-resistant properties of WPC wall panels are a critical aspect to evaluate when considering their use in construction.

Through fire performance testing and the incorporation of additives and treatments, the fire resistance of WPC wall panels can be enhanced.

However, it is essential to adhere to local building regulations and consider the specific requirements of fire-prone environments.

Continued research and development in this field will contribute to the further improvement of WPC materials and their fire-resistant properties, ensuring their safe and effective use in the construction industry.

In conclusion, the fire-resistant properties of WPC wall panels are of utmost importance in ensuring the safety and durability of construction projects.

While WPC wall panels offer numerous benefits such as visual appeal, durability, and low maintenance, their fire resistance remains a key consideration.

Through fire performance testing and the incorporation of flame retardant additives and surface treatments, the fire resistance of WPC wall panels can be significantly enhanced.

These measures inhibit the ignition and spread of flames, reduce smoke development, and minimize heat release rate.

Such improvements contribute to the overall fire safety of structures where WPC wall panels are utilized.

However, it is essential to note that compliance with local building codes and regulations is paramount.

Adhering to these standards ensures that the use of WPC wall panels aligns with fire safety requirements in different environments, including fire-prone areas.

Additionally, proper installation, regular maintenance, and adherence to manufacturer guidelines play a vital role in preserving the fire-resistant properties of WPC wall panels over time.

Continued research and development efforts in the field of WPC materials will contribute to further advancements in fire-resistant properties.

Innovations in manufacturing techniques, additives, and surface treatments will enable the production of WPC wall panels that exhibit even higher levels of fire resistance, meeting and exceeding the stringent demands of the construction industry.

In conclusion, while WPC wall panels offer numerous advantages in construction, including their visual appeal and durability, their fire-resistant properties are crucial considerations.

By incorporating flame retardant additives, applying surface treatments, and ensuring compliance with safety regulations, WPC wall panels can be used effectively and safely in a wide range of applications.

With ongoing advancements, WPC materials have the potential to provide durable and aesthetically pleasing solutions that prioritize fire safety in the built environment.